OEM/ODM/SKD/CKD

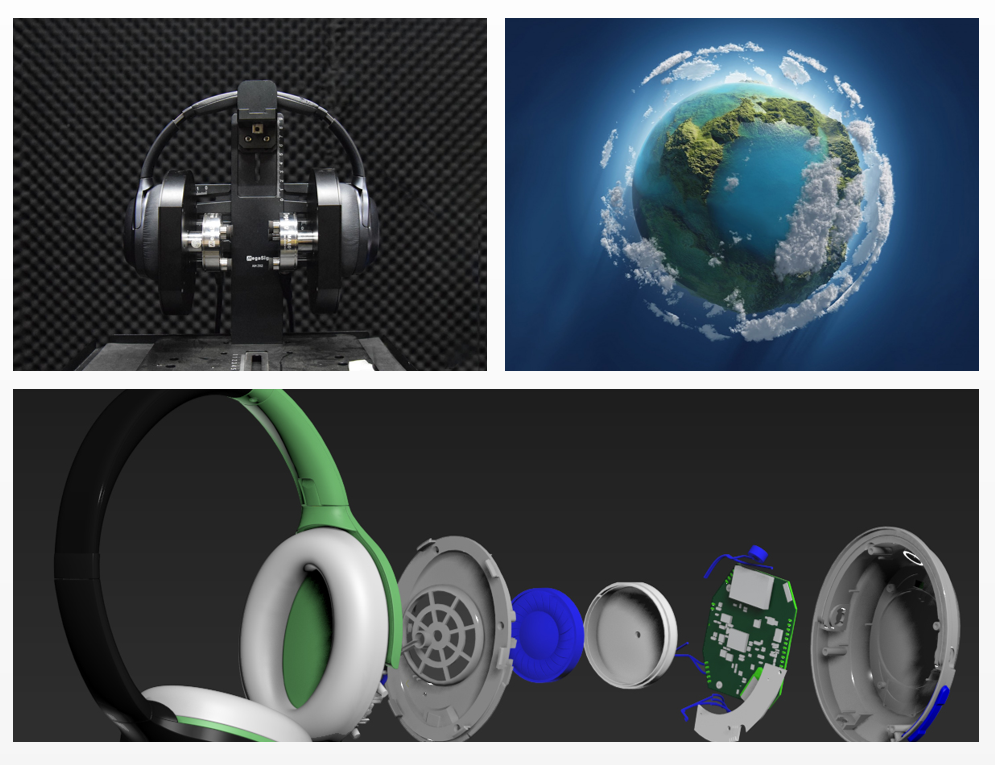

Emphasis on environmentally friendly technology and green manufacturing experience

Introduction to Headphone ODM/OEM Services

We are a professional provider of ODM (Original Design Manufacturing) and OEM (Original Equipment Manufacturing) services for headphones, offering comprehensive customized audio product solutions. Whether you are a brand owner, retailer, or distributor, we are here to meet your needs and help you achieve product differentiation and market competitiveness.

ODM Services

We have a strong R&D team providing one-stop services from concept design to product delivery:

- Product Design: Develop unique headphone designs and features based on your requirements.

- Technology Development: Support advanced features such as active noise cancellation, Wireless connectivity, ambient sound modes, and more.

- Sample Production: Quickly respond to requests and complete function validation and design optimization.

- Manufacturing: Equipped with modern production lines and strict quality control systems to ensure product reliability and stability.

OEM Services

If you already have a mature product design, we offer efficient contract manufacturing:

- Production Optimization: Enhance materials and processes to improve cost-effectiveness and production efficiency.

- Brand Customization: Support personalized requirements such as logo customization and packaging design to enhance brand recognition.

- Fast Delivery: Ensure timely completion of large-scale order production.

Introduction to Headphone SKD/CKD Services

We offer professional SKD (Semi-Knocked Down) and CKD (Completely Knocked Down) services for headphones, providing flexible and efficient production and assembly solutions for clients worldwide. These services are ideal for clients with in-house assembly capabilities, enabling cost-effective logistics, simplified import processes, and localized production to meet diverse market needs.

SKD Services (Semi-Knocked Down)

SKD services provide partially assembled headphone kits, suitable for factories with basic assembly capabilities:

- Pre-Assembled Components: Key parts such as headphone housings, speaker units, and PCBs are pre-assembled.

- Modular Design: Simplifies complex processes, reducing assembly difficulty for clients.

- Flexible Configuration: Offers multiple component combinations based on client needs.

CKD Services (Completely Knocked Down)

CKD services provide fully disassembled headphone kits, ideal for clients requiring complete localization or in-depth customization:

- Complete Components: Includes all parts, such as headphone housings, speaker units, batteries, and PCBs.

- Full Self-Assembly: Allows clients to perform complete localization of assembly and debugging.

- Customization Options: Supports component selection, material customization, and feature extensions.

Years of Expertise

The Trusted Choice for Headphone Manufacturing

With years of experience in headphone manufacturing, we have become the trusted partner for numerous renowned global brands. From high-fidelity sound quality to advanced noise-cancellation technology, every project reflects our commitment to quality and innovation. Whether it’s product development, process optimization, or mass production, we deliver comprehensive solutions for our clients.

Our Advantages

- Extensive Experience: Over 10 years of experience in the headphone industry, serving clients worldwide.

- Professional Team: A team of experts in acoustics, design, and manufacturing dedicated to delivering high-quality products.

- Flexible Solutions: Support for multi-category and small-batch customization to meet diverse market demands.

- Quality Assurance: Strict quality management systems that comply with international certification standards (e.g., CE, FCC, RoHS).

- Sustainability: Focus on eco-friendly materials and energy-saving production processes for a responsible future.

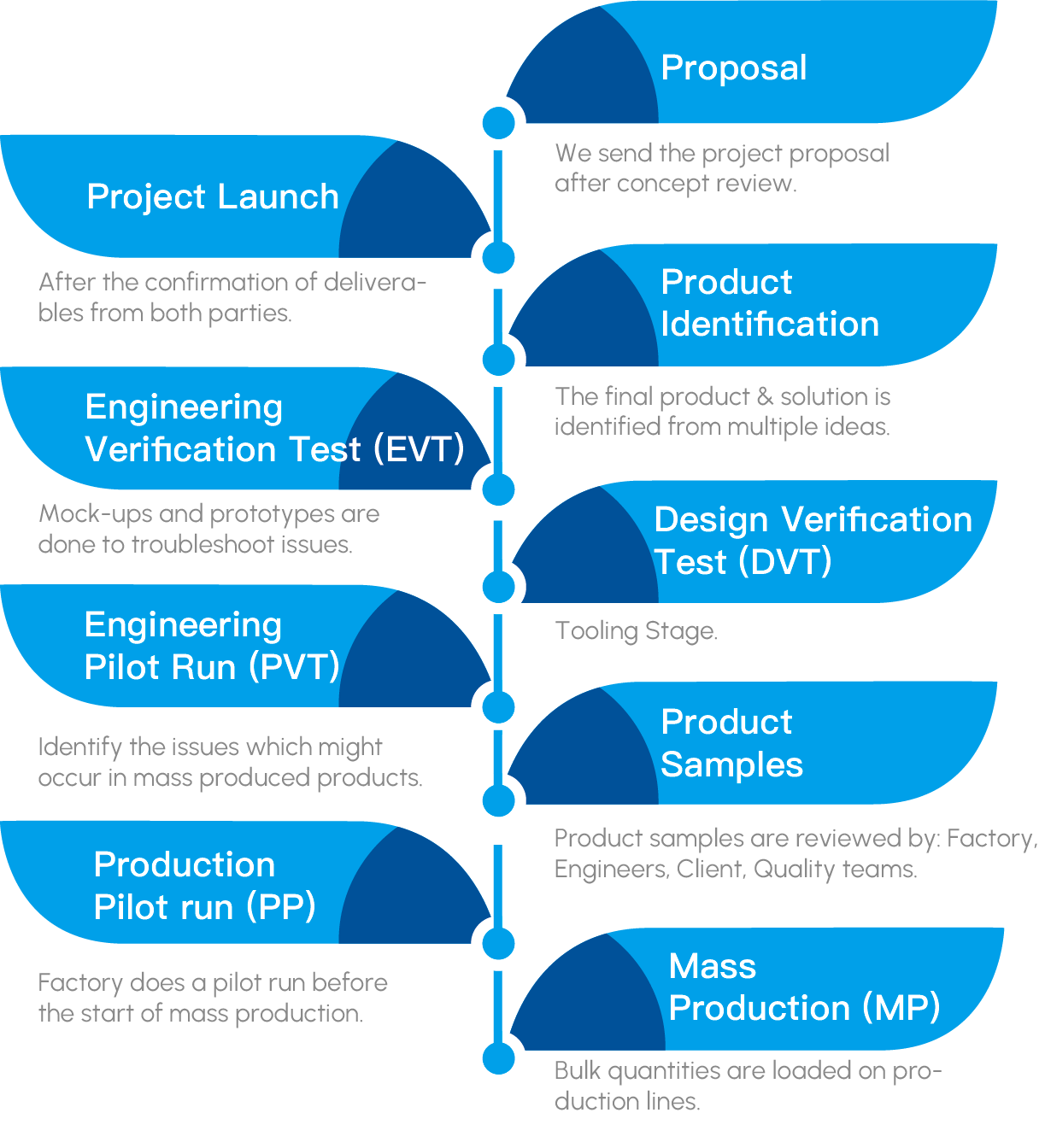

Collaboration Process

- Requirement Discussion: Understand client needs and determine the direction of cooperation.

- Solution Proposal: Provide detailed design, technical, and production plans.

- Sample Confirmation: Clients approve the samples and adjustments are made until satisfaction is achieved.

- Mass Production: Start large-scale production with comprehensive quality monitoring.

- Delivery and Support: Deliver products on time and offer ongoing support services.