Quality Control

Honsenn is an experienced Bluetooth headphones & TWS developer and manufacturer. We provide the products with the best quality of all aspects. Quality control through out the whole process to help customers better.

Quality Control Through-out the Whole Process

As a reputable headphone manufacturer, Honsenn’s quality control management takes over the whole process from the beginning to shipment. As there are different stages and aims, quality control processes are divided into 5 parts: DQE, IQC, IPQC, FQC and OQC.

DQE: Design Quality Engineering

There are design quality engineers involve in the R&D process and make sure that all developing stages meet the requirements, such as environmental and safety regulations, product reliability and other functional requirements.

IQC: Incoming Quality Control

It is the quality confirmation and inspection of the raw materials and parts purchased. When the raw materials or parts arrived, they’ll be by sampling and engineering documents. Those are inspected will be rejected or accepted, IQC not only affects the quality of a company’s final products, but also affects a variety of direct and indirect costs.

IPQC: In-Process Quality Control

It is the process where the quality control implemented in the process from raw material production to product packaging. Our QC members will conduct random inspections on the product quality of each process; check the operation methods and handling of the operators in each process according to SOP.

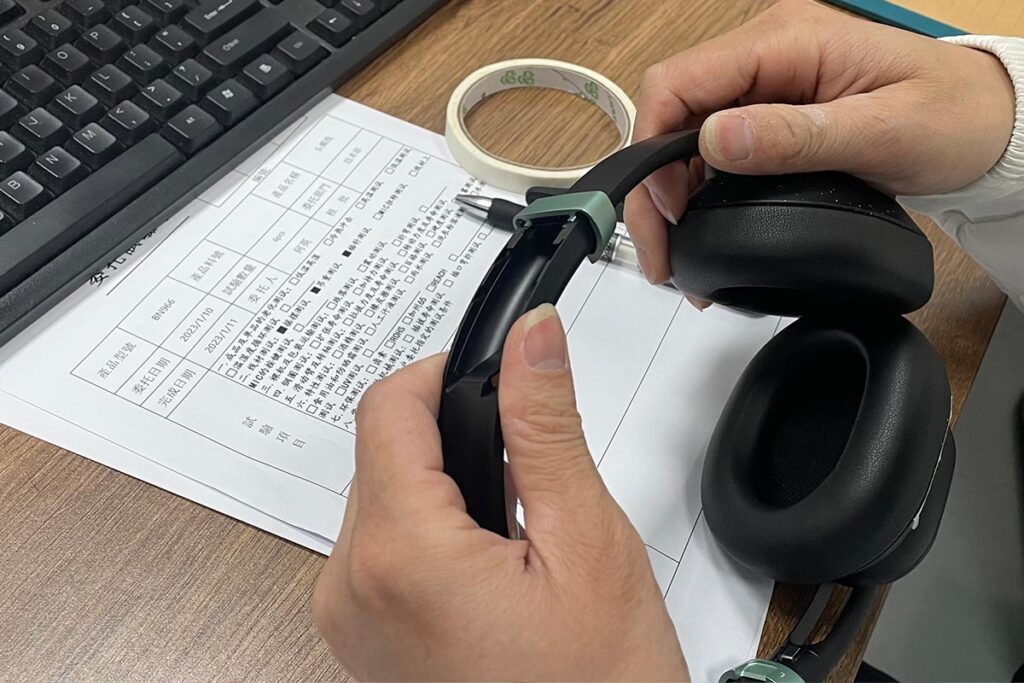

FQC: Final Quality Control

This is the final quality control before the product is packaged or packed. The quality control at this stage is mainly the appearance inspection and performance inspection. Such as color, gloss, roughness, burr, whether there are scratches; Physical or chemical properties, electrical properties, mechanical properties, operational control, etc. The purpose is to ensure that the headphones meet customer’s Fitness for Requirement. So, different levels of product defects (critical, major, and minor) must be detected at this stage, and send them to repair area. Headphones will be 100% inspected at this stage.

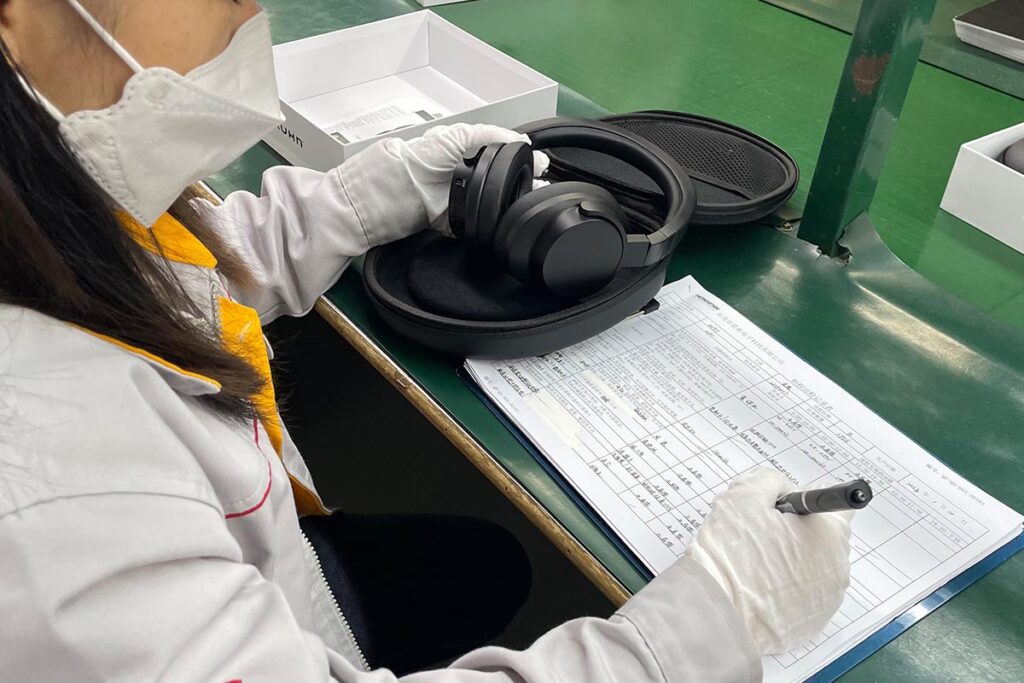

OQC: Outgoing Quality Control

Usually customer will assign inspectors to our factory and have random inspection before shipment. The standards are agreed by the contract or order between both parties. This is mainly focus on the product full functionality test, packaging status, labeling, manual, accessories, etc. With all the quality control processes above, OQC will be smooth and successfully done.

JOIN OUR NEWSLETTER

Let us know your requirements, we can create better than you can imagine.